Introduction:

Talc, a naturally occurring mineral composed of magnesium, silicon, and oxygen, has been utilized for centuries for its remarkable properties and versatile applications. Among its many uses, talc has gained prominence as a filler in various industries. In this blog post, we will explore why talc is extensively used as a filler, shedding light on its unique characteristics and benefits. Ashirwad Minerals, a renowned manufacturer and supplier of Talc powder for Natural Filler Compound, takes pride in presenting this informative piece on the significance of talc as a filler.

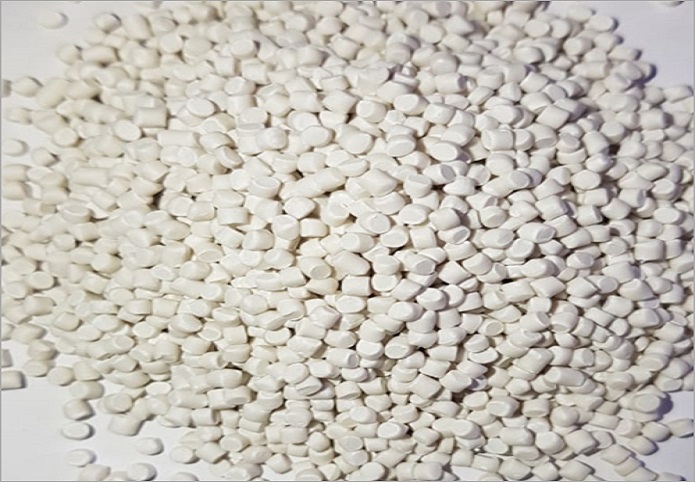

Definition and Properties of Talc

Talc is renowned for its softness, smoothness, and low abrasiveness, making it an ideal material for numerous industrial applications. It possesses a layered structure that gives rise to its distinctive characteristics. It is chemically inert, has a high aspect ratio, and exhibits excellent dispersibility, making it an exceptional filler choice.

Enhancing Product Performance

Talc acts as a filler in various industries, primarily because of its ability to enhance product performance. By incorporating talc into a product, manufacturers can achieve several benefits:

Cost-Effective Solution

Another significant advantage of using talc as a filler is its cost-effectiveness. It is readily available in abundant quantities worldwide, making it a cost-efficient option for manufacturers. Compared to other fillers, this mineral offers a balance between performance and cost, making it an attractive choice for a wide range of applications.

Aesthetic and Functional Advantages

In addition to enhancing performance, talc provides aesthetic and functional benefits to products:

Environmental Considerations

Talc is a naturally occurring mineral, and its use as a filler aligns with sustainable practices. It is non-toxic, chemically inert, and can be safely disposed of without harming the environment. Furthermore, its ability to enhance the performance of materials can contribute to the development of more durable and long-lasting products, reducing waste and promoting sustainability.

Conclusion

Talc's exceptional properties and numerous benefits make it an ideal choice as a filler in various industries. Its ability to enhance product performance, cost-effectiveness, aesthetic advantages, and environmental considerations contribute to its widespread utilization. As a trusted manufacturer and supplier of talc powder, Ashirwad Minerals recognizes and embraces the importance of talc as a versatile filler, and remains committed to providing high-quality talc products to meet the diverse needs of industries worldwide. By harnessing the potential of talc as a filler, manufacturers can unlock a world of possibilities, creating innovative and superior products that cater to the demands of a dynamic market.