Introduction:

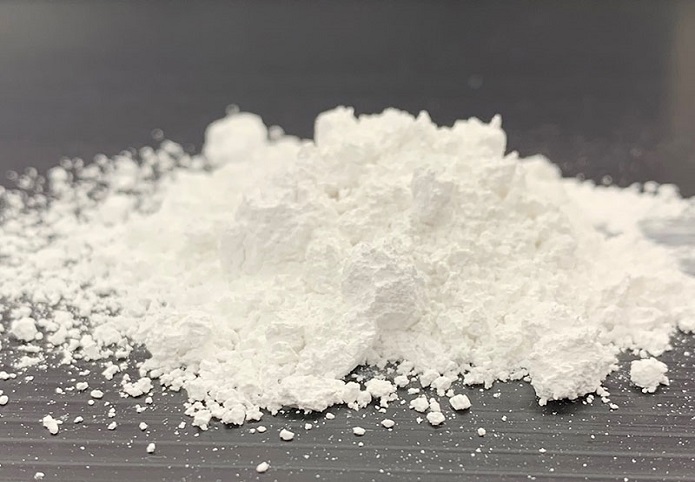

In the ever-evolving world of plastics manufacturing, the quest for improved mechanical properties, enhanced aesthetics, and cost-effective solutions is unceasing. One such solution that has gained prominence is the addition of talc powder to various types of plastics. Talc, a naturally occurring mineral, brings a host of benefits to plastics, making it a sought-after choice in numerous industries. In this blog post, we'll explore the types of plastics that can benefit from the addition of talc powder and the advantages it brings to each application.

Polypropylene (PP): A Prime Candidate

Polypropylene (PP) stands as one of the most commonly used plastics where talc addition demonstrates remarkable benefits. The versatility of PP, coupled with its moderate strength, impact resistance, and cost-effectiveness, makes it an ideal candidate for numerous applications. Talc's ability to enhance stiffness and dimensional stability makes it a perfect partner for PP, resulting in improved mechanical performance and reduced warpage during molding. From automotive parts to consumer goods, talc-filled PP finds its way into a plethora of products, imparting durability and visual appeal.

Polyethylene (PE): Elevating Performance

Polyethylene (PE), another widely used plastic, often benefits from the incorporation of talc powder. PE is known for its flexibility and chemical resistance, but sometimes it lacks the required stiffness for specific applications. By adding talc, manufacturers can significantly improve PE's stiffness and dimensional stability without compromising its inherent properties. This enhancement is particularly valuable in applications where rigidity and stability are crucial, such as industrial containers, toys, and electrical components.

Polyamide (PA): Striking the Balance

Polyamides (PA), also known as nylons, are versatile plastics with excellent mechanical properties and thermal resistance. Talc's addition to PA can help strike a balance between stiffness and impact resistance. In applications like automotive parts and industrial components, talc-filled PA exhibits reduced wear and improved performance under varying temperature conditions. This combination of properties makes talc-filled PA a top choice for engineering applications demanding robustness and versatility.

Polystyrene (PS): Enhancing Appearance and Properties

Polystyrene (PS) is commonly used in a range of products, from disposable cutlery to electronic housings. While PS is known for its clarity and ease of processing, it can lack certain mechanical properties. Talc's addition to PS can improve its stiffness, impact resistance, and dimensional stability, making it suitable for applications requiring enhanced performance. Additionally, talc can provide a matte or satin-like finish to the surface, enhancing the overall aesthetics of the product.

Polyvinyl Chloride (PVC): Adding Value

Polyvinyl chloride (PVC) is renowned for its chemical resistance, electrical insulation, and cost-effectiveness. In certain applications, such as pipes and profiles, the addition of talc can contribute to improved dimensional stability, reduced thermal expansion, and enhanced resistance to external stressors. By incorporating Talc powder for plastics, manufacturers can create PVC products with extended service life and enhanced overall value.

Conclusion

Talc powder's remarkable benefits have positioned it as a valuable additive in various types of plastics, enhancing their mechanical properties, aesthetics, and overall performance. From polypropylene and polyethylene to polyamide, polystyrene, and polyvinyl chloride, talc has found its way into a wide range of plastics, transforming them into materials capable of meeting diverse industrial and consumer demands. As industries continue to seek innovative solutions, talc-filled plastics stand as a testament to the power of collaboration between natural minerals and modern manufacturing techniques.

At Ashirwad Minerals, we understand the importance of talc's role in enhancing plastics. With our commitment to quality and innovation, we provide premium talc powder to empower industries with the tools they need to create superior plastic products. Contact us today to learn more about how talc can elevate your plastic applications to new heights of performance and excellence.