Introduction:

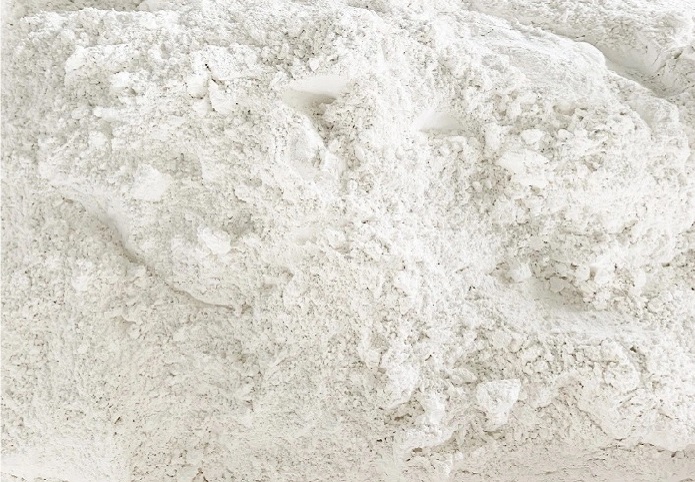

The plastic industry has revolutionized the modern world, offering countless applications across various sectors. To enhance the performance and properties of plastic materials, manufacturers often incorporate additives. Among these additives, talc powder stands out as a versatile and widely used ingredient. In this blog post, Ashirwad Minerals will explore the various applications of talc powder in the plastic industry and its significant contributions to improving plastic properties.

Enhancing Mechanical Properties

Talc powder plays a crucial role in improving the mechanical properties of plastic materials. When added to plastics, it acts as a reinforcing filler, enhancing strength, stiffness, and dimensional stability. The lamellar structure of talc particles reinforces the polymer matrix, reducing the risk of deformation and increasing resistance to impact. By incorporating this mineral, manufacturers can produce plastic products with enhanced mechanical strength and durability.

Improving Thermal Resistance

Plastic materials often face challenges related to heat resistance. Talc powder serves as an effective solution in such cases, as it exhibits excellent thermal stability. When blended with plastic resins, it acts as a heat sink, absorbing and dissipating heat, thus preventing premature melting or deformation of the plastic. This property allows plastic products to withstand higher temperatures, making them suitable for applications where heat resistance is required.

Enhancing Chemical Resistance

Chemical resistance is another vital aspect of plastic materials, particularly in industries dealing with harsh chemical environments. Talc powder is known for its inert nature and resistance to various chemicals, making it an ideal additive for enhancing the chemical resistance of plastics. By incorporating Talc powder for PVC can better withstand exposure to acids, alkalis, oils, and other corrosive substances, ensuring longevity and maintaining their structural integrity.

Improving Electrical Properties

Talc powder also plays a significant role in improving the electrical properties of plastic materials. When added to plastics, it acts as an insulator, reducing the risk of electrical conductivity. This makes this compound an essential ingredient in electrical and electronic applications, where insulation and protection against electrical current are crucial. By incorporating this mineral, manufacturers can produce plastic components with enhanced electrical insulation, minimizing the risk of short circuits and other electrical hazards.

Enhancing Processing and Extrusion

The addition of talc powder to plastic formulations offers several benefits during processing and extrusion. It acts as a lubricant, reducing friction between polymer particles, which leads to improved flow and easier processing. This property facilitates the manufacturing of complex plastic products with intricate shapes. Moreover, it helps prevent the sticking of the plastic material to processing equipment, enhancing productivity and reducing downtime for cleaning and maintenance.

Improving Aesthetics and Surface Finish

Talc powder is widely utilized in the plastic industry to enhance the aesthetics and surface finish of plastic products. Due to its fine particle size and lamellar structure, talc imparts a smooth and matte appearance to plastic surfaces. This property is particularly valuable in applications such as automotive parts, household appliances, and consumer goods, where a visually appealing finish is desired. It also acts as a filler, reducing the visibility of imperfections and improving the overall surface quality of plastic products.

Conclusion

Talc powder is an indispensable additive in the plastic industry, offering numerous benefits and improvements to plastic materials. Its ability to enhance mechanical properties, thermal resistance, chemical resistance, electrical properties, and processing characteristics make it highly sought-after by manufacturers. By incorporating this mineral, the plastic industry can produce high-quality products that meet the demanding requirements of various sectors. As a versatile and reliable additive, talc continues to play a vital role in shaping the future of the plastic industry.