Microsilica is particularly compatible with calcium aluminate cements, and the use of microsilica prevents the conversion of high-alumina cement, according to published reports. The utilisation of calcium aluminate cement and microsilica in combination is a critical component of modern refractory technology.

Fibreglass and silica textiles are beneficial in high-temperature situations for a variety of sealing and protective applications.

The mechanical qualities of the sheet, including tensile strength, bending strength, and stiffness, can also be increased by talc. Arm sensibility has also increased, allowing for a more colourful, pearl-like appearance of the sheet.

While fibreglass and silica are sometimes mistaken, they are two completely different materials. Silica is almost entirely composed of silica sand, with only a few additional components. Fiberglass is made up of roughly 65 percent silica and the rest is made up of various chemicals. While each of these materials have similar advantages, they are produced in distinct ways.

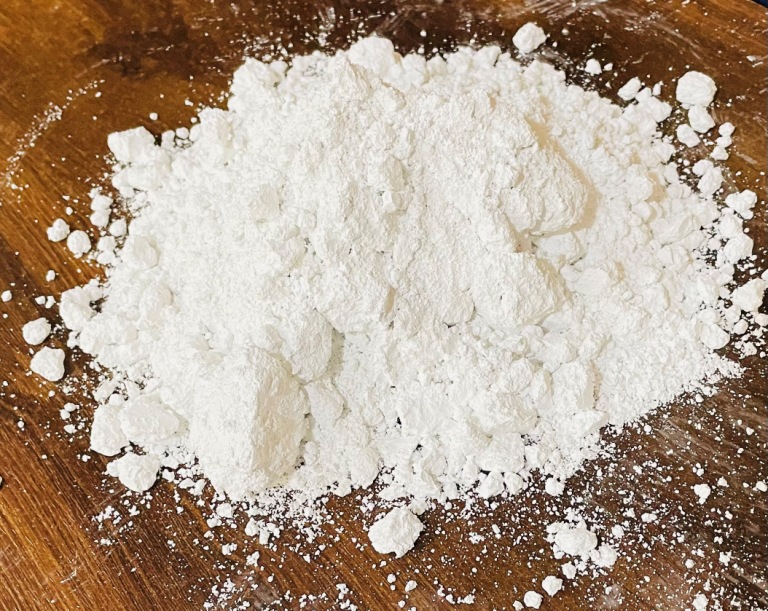

Origin of Silica fume, features, and physical qualities:

Silica fume, also known as microsilica, is a noncrystalline polymorph of silica formed as a by-product of silicon and ferrosilicon alloy manufacturing in electric arc furnaces (EAFs). Although the earliest trials of silica fume as a concrete component occurred in the 1950s, almost all of the silica fume was simply released to the atmosphere at the time. Silica fume began to be stored in bag filters only after heightened environmental laws in the late 1960s, prompting producers to look for a use for the waste. A potential market was created after preliminary investigations in Norway revealed silica fume's potential for improving concrete durability.

Silica fume is mostly made up of amorphous silica. The exact silica percentage varies depending on the source of the silica fume, although it is always greater than 85%. Crystobalite, a kind of crystalline silica, is found in small quantities. Other trace pollutants include carbon (from the addition of coke and wood chips during the manufacturing process), aluminium, iron, calcium, magnesium, potassium, and sodium, in roughly decreasing amounts.

- Applications of Micro Silica Powder for FRP Fibreglass

- Corrosion Resistance: Micro-lower silica's permeability protects against chloride ion intrusion, extending the time it takes for ionic compounds to reach the piece of steel and initiate corrosion. Furthermore, micro-silica has a substantially higher electrical resistance, which slows the rate of deterioration. This combined effect extends a structure's life by 5–10 times.

- Heat Reduction: For concrete of the same strength, partially replacing with condensed silica fume and measuring its efficiency factor results in a reduced maximum rising temperature and temperature difference. It has also been shown to be the most effective method for producing low-heat concrete without compromising strength at an early stage.

- Abrasion Resistance: Silica fume have a strong abrasion resistance. The use of silica fume concrete in the construction of floors and pavements saves time and money. It also increases the facility operator's operational efficiency. Concrete's hydraulic abrasion-erosion resistance has been improved, making it ideal for the building of dam spillways.

- Chemical Resistance: Micro silica is used extensively in industrial constructions that are subjected to a variety of harsh chemicals. In the chemical sector, workers are exposed to alkaline solutions, phosphates, nitrates, petrochemicals, and other chemicals. As a result, it is extremely useful in both the industrial and agricultural sectors.

Both pfa and ggbs are compatible with microsilica. Microsilica can be added to improve early age stiffness, as it reacts faster in the first three days, or to enhance the consistency of fresh concrete provided strong exchange levels of pfa or ggbs are employed. High amounts of ggbs replacement might produce bleed water issues, not only on the surface of the concrete but also within the matrix. The microsilica will essentially reduce the bleed effect, preserving the concrete's integrity.